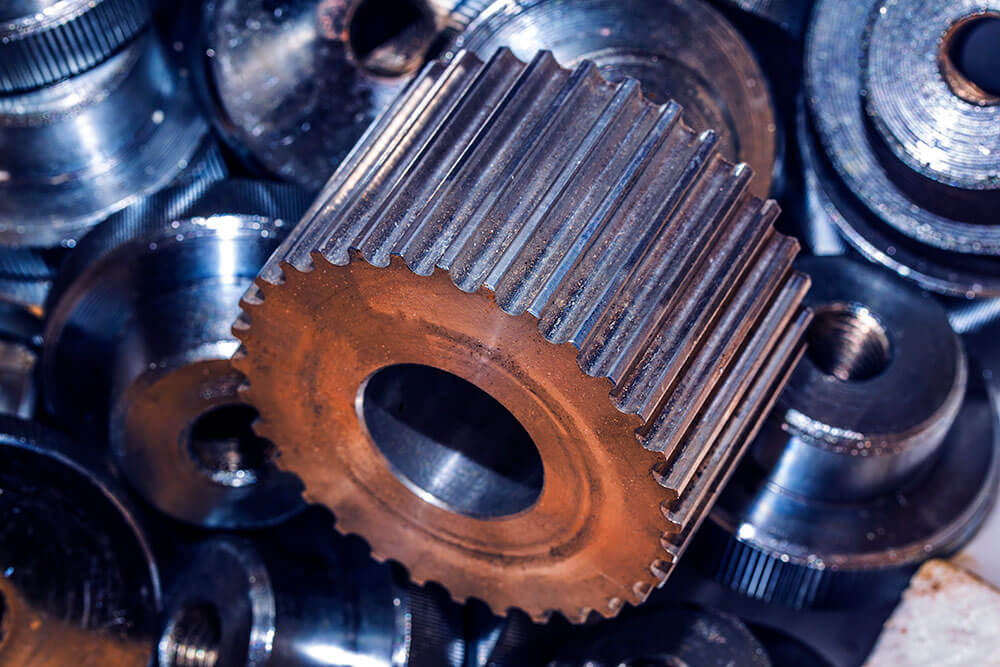

Abrasive shot blasting is a widely used process for preparing metallic surfaces for painting, corrosion protection, or other coatings. The most commonly used type of shot blasting machine for this purpose is the Apron Shot Blasting Machine. This machine has several advantages in comparison with the other methods of shot blasting, which you will explore in this article. A Shot Blasting Machine is a machine designed to blast surfaces with either air pressures or centrifugal wheel and with different abrasives, such as sand, steel shot, or steel grit. These machines use a system of rollers to lift the part creating a gap between the part and the blasting chamber. This gap allows for a more effective and efficient operation, as the shot blasting media used has more room to work in and does not have to move around tight spaces. This article will discuss the advantages of using an Apron Shot Blasting Machine for your industrial or manufacturing needs. We will look at how this machine’s increased speed of operation, ability to work with multiple types of materials, decreased wear and tear on component parts and low operating costs make it a superior choice for many applications. Additionally, this article will discuss the superior surface finish and versatility that are possible with an Apron Shot Blasting Machine. Finally, this article will provide a summary of the advantages of an Apron Shot Blasting Machine and a discussion of why this machine might be a good option for your application.

Advantages

The Apron Shot Blasting Machine offers several advantages over other shot blasting methods. Firstly, the increased speed of operation makes it a more efficient and faster method than more traditional blasting techniques. Secondly, the ability of the this machine to work with multiple types of materials, such as steel shot, steel grit, and other abrasives, makes it a very versatile and adaptable choice. Thirdly, the decreased wear and tear on component parts, which translates to an overall lower cost of operation for the machine, results in cost savings over the long run. Finally, the superior surface finish offered by the Apron Shot Blasting Machine is difficult to match with other methods and results in a higher quality product. With these advantages combined, a Shot Blasting Machine is an excellent choice for many industrial and manufacturing applications.

Increased Speed of Operation

One of the greatest advantages of the Apron Shot Blasting Machine is its increased speed of operation. When compared to other shot blasting methods, the apron design of the this machine enables a more efficient operation with more parts being processed in a shorter period of time. As more of the blasting media is able to move around the part easily, the blasting process is able to occur faster without sacrificing quality. This increased speed of operation means a higher throughput, resulting in more parts produced in a shorter period of time. Additionally, the increased speed of operation translates to lower production costs and higher profits for the organization. If you have any questions during using Shot Blasting Machine, you can contact our expert team at any time to solve your questions.

Ability to Work with Multiple Types of Materials

Another advantage of the Apron Shot Blasting Machine is its ability to work with multiple types of materials. This machine uses a system of rollers to lift the part and to create a gap between the part and the blasting chamber. This gap allows for the shot blasting media used to be more effective and to work in a more versatile way. This allows the Apron Shot Blasting Machine to use different abrasives such as sand, steel shot, steel grit, and other materials. This versatility means that this type of shot blasting machine can be used in different types of applications. Furthermore, it also allows for the workload to be distributed among a variety of media, which helps to keep the shot blasting process running smoothly and efficiently.

Decreased Wear and Tear on Component Parts

The Apron Shot Blasting Machine also offers a advantage in terms of decreased wear and tear on component parts during the shot blasting process. The gap created between the part and the blasting chamber allow for less abrasive media to be needed to achieve the desired shot blasting results. This increases the life of the blasting equipment as well as the part being blasted, and also results in lower operating costs in the long run. This decrease in wear and tear on component parts is a major advantage of the Apron Shot Blasting Machine, and will result in higher productivity and greater cost savings in the long run.

Low Operating Costs

The Apron Shot Blasting Machine also offers low operating costs, which makes it an attractive option for many applications. The machine’s increased speed of operation and decreased wear and tear on component parts results in less expenditure of time and money on the shot blasting process. In addition, the use of multiple types of media allows for the workload to be distributed more evenly over the different types, resulting in fewer replacement parts being needed over the long run. All these factors combine to make the Apron Shot Blasting Machine an exceptionally cost effective and efficient machine for many industries.

Superior Surface Finish

The Apron Shot Blasting Machine also offers superior surface finish results. The gap created between the part and the blasting chamber enables the blasting media to move faster and more effectively, resulting in a smoother surface finish. Furthermore, the versatility of the machine allows for the use of different types of media in order to achieve the desired results for any application. The end result is a superior surface finish that is difficult to match through other methods, resulting in a higher quality product.

Versatility

The Apron Shot Blasting Machine is incredibly versatile, allowing for use in a wide range of industrial and manufacturing applications. Its ability to work with multiple types of media, such as sand, steel shot, and steel grit, means that it can be used in a variety of situations, such as cleaning and deburring of parts. Additionally, the low operating costs and increased speed of operation mean that the Apron Shot Blasting Machine can be used for large-scale production, as well as for smaller-scale operations. This versatility makes it a great choice for many different types of operations.

Conclusion

In conclusion, the Apron Shot Blasting Machine is a highly effective tool for many industrial and manufacturing applications. Its list of advantages, including increased speed of operation, ability to work with multiple types of materials, decreased wear and tear on component parts, low operating costs, superior surface finish, and versatility, make it an ideal choice for many different types of projects.

Summary of Advantages of Apron Shot Blasting Machine

The Apron Shot Blasting Machine offers a great range of advantages for industrial, manufacturing, and other applications. The machine is capable of increased speed of operation, working with multiple types of materials, decreased wear and tear on component parts, low operating costs, and superior surface finish. Additionally, it can be used in a wide range of applications due to its versatility, allowing it to satisfy the needs of many different businesses. Taking all these advantages into account, an Apron Shot Blasting Machine is an ideal choice for many industrial and manufacturing applications.

Final Thoughts on Why an Apron Shot Blasting Machine Might be a Good Option for Your Application

Overall, the Apron Shot Blasting Machine is a great choice for many industrial and manufacturing applications. With its ability to work with multiple types of media, increased speed of operation, decreased wear and tear on component parts, low operating costs, superior surface finish, and versatility, this type of shot blasting machine can meet the needs of many different businesses. When it comes to getting the job done quickly, efficiently, and cost-effectively, the Apron Shot Blasting Machine is the perfect choice. Shotblastingmach.com also provide different type of Shot Blasting Machines to match your need.